Mining for crude oil using traditional methods, as practiced in Wonocolo Village, Kedewan District, Bojonegoro, requires significant capital. The stench of exhaust fumes can be smelled from hundreds of meters away. The closer you get, the thicker the air pollution.

Soon, dozens of used diesel truck engines roar loudly. Then, a steel rope wrapped around a large wooden reel is spun. The steel rope continues to rotate and is pulled upward. As it rises, the engine noise grows louder. The steel rope, about 200 meters long, is rapidly rolled up. A moment later, the 5-meter-diameter steel pipe emerges and hits the ground. "Blow!" A yellow-brown liquid gushes from the bottom end of the pipe, which touches the ground.

The steel pipe is suspended from three teak pegs 12 meters high. The pungent, sulfur-smelling liquid flows into a greenish-black reservoir. The water settles, a thick liquid floating. The water flows into a lower reservoir through a 2-meter-diameter pipe. Once the liquid is gone, the steel pipe is pulled back. And so on. These are the daily activities of traditional oil miners in the forests of Wonocolo Village, Kedewan District, Bojonegoro, East Java.

Three years ago, a number of traditional miners were still pulling steel cables by hand. This was a common activity for miners with limited capital. Previously, to obtain crude oil, workers had to descend into valleys and pull hundreds of meters of steel cables by hand; like machines, these oil workers had to fish oil pipes from the earth's crust. In a day, only one drum of crude oil was hauled up.

However, the oil workers were now content. With changing times, as capital increased, miners replaced their labor with machines. Dozens of diesel engines, Fuso trucks, and vintage Mercedes-Benz 911s, roaring daily, replaced the laborers. These activities lasted from dawn to dusk. The local community carried out oil mining practices in the midst of the forest.

However, now the mined forest area is almost devoid of vegetation. Perhaps dozens, if not hundreds, of hectares of surrounding forest have been severely damaged by traditional oil mining, and thousands of teak trees have been cut down for oil mining purposes. The river water is no longer clear, polluted by crude oil sludge.

A blackish-brown foam dominates the water flow around the mine site, likely due to pollution from mining activities in the area.

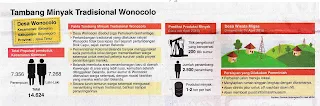

The local community only knows that hundreds of oil wells have been managed since the Dutch colonial era in 1894. To this day, the area continues to be explored by hundreds of traditional miners. However, the miners don't get the crude oil for free.

The oil porters must spend a significant amount of money. Today, we need around Rp 200 million to Rp 300 million to extract oil. The large capital outlay is due to the extremely expensive equipment required.

For example, buying a used truck requires more than Rp 75 million. The same goes for purchasing iron pipes and modified steel pipes to extract oil from the earth.

The hundreds of millions of rupiah were raised through a pooling of dozens of people who would manage the oil well. The managers also had to allocate significant funds for the preparation costs of draining the well until the oil came out.

Media Indonesia, Page-2, Wednesday, Nop 2, 2016

No comments:

Post a Comment